Ace Super Series Lugger

Industry’s Workhorse for over 60 Years.

When it comes to the ultimate lugger hoist. Look no further than an Ace Lugger Hoist!

Cargo Securement of Lugger Containers

Ace Super Series Lugger Contact Pin Cylinders Comply with Cargo Securement Requirements with containers 48" or taller without any additional modifications!

Title 49: § 393.102 Compliant

Follow link below for Ace's Cargo Securement Engineering Study

Lightest Tare Weight of any Roll-Off Trailer

Best in Class Maneuverability

Dual Lift & Reeving Cylinders

CONTAINER SIZES: 5-60 CUBIC YARD

Wireless Remote Control (option)

Gross Vehicle Weight

Cost and Savings Summary

Savings and Additional Potential Revenue Gain Over a Roll-off Truck (Straight Truck)

| Cost & Savings of ART-60-25* | ART-60-25* & Tractor |

| Payload Gain Per Haul | 17,600 – 18,700 lbs. |

| Savings on ART-60-25* & New Tractor | $47,050.00 +/- |

| Fuel Savings Per Tractor per Year | $8,070.00 – 12,105.00 +/- |

| Fuel Savings Per Tractor Over 5 Years |

$40,350.00 - 60,525.00 +/- |

* Estimate

| LEGAL PAYLOAD | ART-60-25* Tandem Axle w/ Lift Axle |

Roll-Off Truck Tandem w/ lift axle |

| Legal GVW | 74,500 GVW | 65,000 GVW |

| Unit Weight | 12,900 lbs. | 8,200 lbs. |

| Tractor/Truck Weight | 17,000 lbs. | 20,000 lbs. |

| 40 Yard Container Weight |

6,000 lbs. |

6,000 lbs. |

| Legal Payload |

38,600 lbs |

21,800 lbs. |

| Legal Payload Gain (per haul) |

17,600 lbs |

N/A |

| HMS #1 Price (Metric Ton) 11/01/2016 |

$195.00 |

$195.00 |

| Payload Gain ($) Per haul |

$1,716.00 |

N/A |

| Payload gain ($) at (5) hauls a day |

$8,580.00 |

N/A |

* Estimate

| FUEL SAVINGS | TRACTOR |

CHASSIS (TRUCK) |

| AVG. Miles Per Gallon (MPG) | 7-10 MPG | 5-7 MPG |

| AVG. Cost Of Diesel Fuel per Gallon | $2.69 | $2.69 |

| AVG. Miles Per Day | 200 Miles | 200 Miles |

| Gallons Needed/Day |

30-42 Gallons |

42 - 60 Gallons |

| AVG Fuel Cost/Day |

$80.70– 112.98 +/- |

$112.98-161.40 +/- |

| AVG. Savings/Day Per Tractor |

$32.28 - 48.42 +/- |

N/A |

| AVG. Savings/Tractor/Year @ 50 Operating Weeks/Year |

$8,070.00 – 12,105.00 +/- |

N/A |

Based on 2017 Kenworth T880 Day Cab Tractor & Kenworth T880 Double Frame Chassis (Truck)

| COST DIFFERENCE | ART-60-25* |

Roll-Off Truck Tandem |

| Cost of New Chassis/Tractor | $120,000.00 +/- | $170,000.00 +/- |

| Cost Of New Unit * | $47,950.00 | $45,000.00 +/- |

| Total of New Chassis/Tractor & Unit | $167,950.00 +/- | $215,000.00+/- |

| Saving On New Tractor & ART-60-25* Over New Chassis & ROTT* | $ +/- Ea. Unit | |

| Saving On New Tractor & ART-60-25* Over Used Chassis & ROTT* | $47,050.00 +/- Ea. Unit |

Based on 2017 Kenworth T880 Day Cab Tractor & Kenworth T880 Double Frame Chassis (Truck)

Product information

| SPECIFICATIONS | ACE | BENEFITS |

| Gross Lifting Capacity | 60,000 lbs. | Highest Capacity in Class |

| Container Capacity | 6-30 Cubic Yards | 6 Cu. Yards More Than Any Competitor's Lugger |

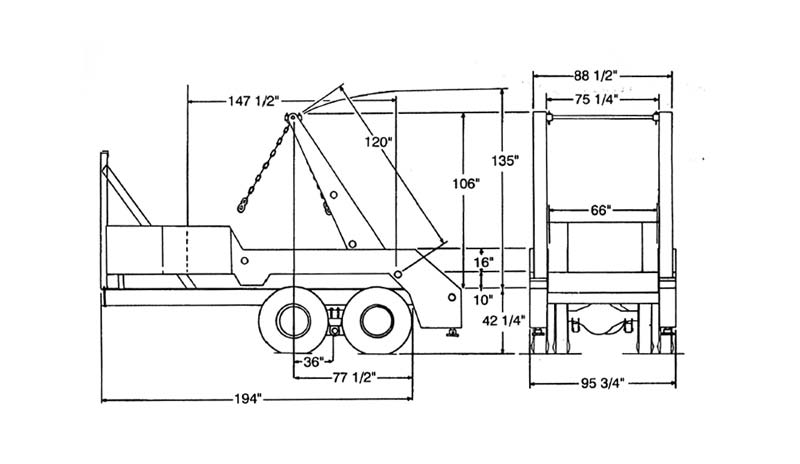

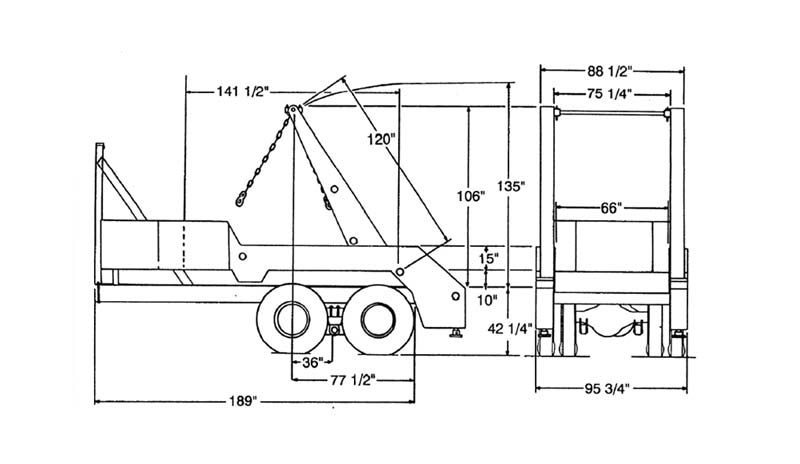

| Dump Degree | 120° | Controlled Dump and Less "Stringing" of Material |

| Arm Length | 120" | Versatility of Container Sizes |

| Operating Pressure | 3400 PSI | |

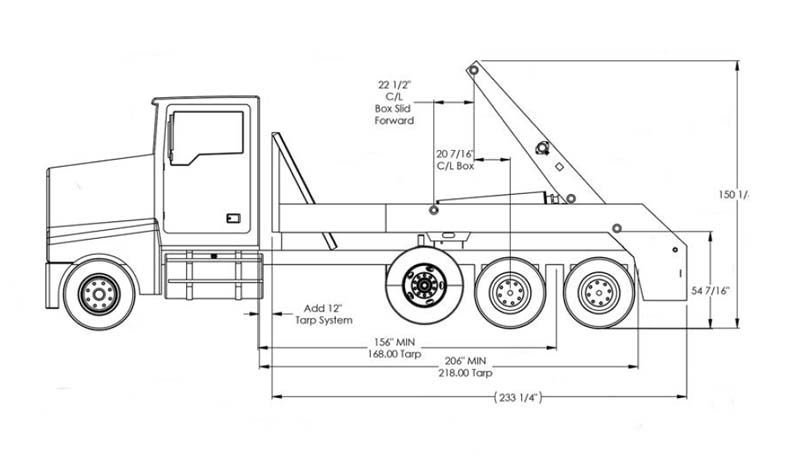

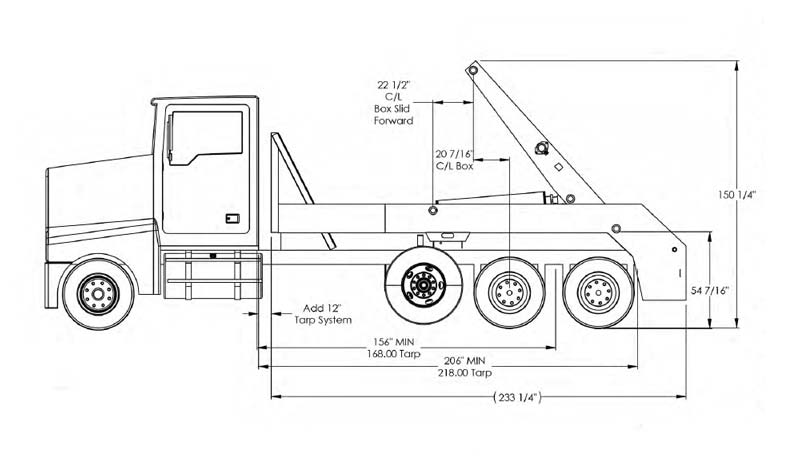

| Weight Distribution | Best in class | Arm Hinge is above bed. This allows the container to be brought 24" farther forward towards the cab. |

| Cycle Time | Lowered Position Raised Position |

59 Seconds 48 Seconds |

| BODY CONSTRUCTION | ||

| Subframe | 10" Structural Channel | Industry Standard |

| Side Boxes | 1/2" Plate 2"x2" Angle Iron Reinforcement |

Thicker and Higher Yield Steel. Longest Life Added Strength, Prevents Sides from Bending |

| Body Floor | 3/8" Formed | |

| Hinge Pins | 3" with Grease Zerks | Higher Yield & Heavier Duty |

| Walking Steps | Both Driver and Passenger Side | Easy Access From Any Direction |

| Cab Protector | 3/8" Angle Iron Welded to Body Frame | More protection, Prevents Container from Shifting |

| Wear Strips | 1/2" x4" Wear Strips | Prevents Damage to Body's Deck |

| Access Panels | Front & Rear of Body | Easy Access to All Components |

| Body Frame Mounts | (4)1/2" Tie Down Rod with 1/2" Plate (8) 5/8"x 2 1/2" Plate with Grade 8 Nuts |

Longer Life than Bolt Clamps Welded to Body, Bolted to Truck Frame |

| ARM CONSTRUCTION | ||

| Arm Construction | 1/2" Steel, One Solid Plate, Square Construction 4x4" Angle Iron Reinforcement |

Square Design is Stronger and Provides Consistant Strength. Added Strength to Arms |

| Arm Hinges | Pin/Collar with Grease Zerks | Long Life Expectancy, Easier Maintenance |

| Drop Pins | Replaces Load Shaft | Easy to repair/replace. Saves hours of labor |

| Cross Bar | 3" 1018 Cold Bar | Stronger and Higher Yield, Lasts longer |

| HYDRAULIC CYLINDERS | ||

| Arm Cylinder | 9 1/2" ID, 3 1/2" Chrome Shaft | All Welded Construction with drop pin connection |

| Contact Cylinder | 2 1/2" shaft w/ Snap Ring for Quick Repair | Can be fixed without removing cylinder from truck |

| Outriggers | Hydraulic Vertical | Fully Enclosed for Protection with Easy Access |

| LOADING & DUMPING OPERATION | ||

| Contact Cylinder | 2 1/2" shaft w/ Snap Ring for Quick Repair | Can be Fixed Without Removing Cylinder from Truck |

| Contact Cylinder Hose | Inside Lift Arm | Protects Hose from Premature Wear |

| Lift Hooks (Front) | 2-4 hole | Largest Versatilty of Containers Can Be Used |

| Dump Keys | Replaced "J" Hook | Safer and Significantly More Controlled Operation |

| Saddle Blocks | 3" x 8" Flame Cut | Allows Chain to Swivel for Level Operation |

| Chain | 5/8" High Alloy Chain | |

| U-Bolts | 1/2"x24" U-Bolt | |

| HYDRAULIC CYLINDERS | ||

| Hydraulic Flow Rate | 35 Gallons Per Minute | |

| Hydraulic LInes | Under Body with Access Panel | Easier to Replace and Simpler Routing |

| Hoses | 3000 PSI with Nylon Sleeves | Safety and Driver Protection is Paramount |

| Oil Tank | 50 Gallon, Truck Fame Mount | Out of Harms Way, Easy to Fill |

| Hydraulic Pump | P-365 Pump | 3500 PSI Operating Pressure |

| Valve | Commercial Valve | Rugged and Reliable Valve |

| In-Cab Controls | Air | Feathering Controls for Precise Operation |

| LIGHTING - ALL L.E.D | ||

| Side Marker, Rear Marker, Reverse, STT, 3- Bar Cluster, License Plate |

| SPECIFICATIONS | ACE | BENEFITS |

| Gross Lifting Capacity | 50,000 lbs. | Highest Capacity in Class |

| Container Capacity | 6-30 Cubic Yards | 6 Cu. Yards More Than Any Competitor's Lugger |

| Dump Degree | 120° | Controlled Dump and Less "Stringing" of Material |

| Arm Length | 120" | Versatility of Container Sizes |

| Operating Pressure | 2500 PSI | |

| Weight Distribution | Best in class | Arm Hinge is above bed. This allows the container to be brought 24" farther forward towards the cab. |

| Cycle Time | Lowered Position Raised Position |

59 Seconds 48 Seconds |

| BODY CONSTRUCTION | ||

| Subframe | 10" Structural Channel | Industry Standard |

| Side Boxes | 1/2" Plate | Thicker and Higher Yield Steel. Longest Life |

| Body Floor | 5/16" Formed | |

| Hinge Pins | 3" with Grease Zerks | Higher Yield & Heavier Duty |

| Walking Steps | Both Driver and Passenger Side | Easy Access From Any Direction |

| Cab Protector | 3/8" Angle Iron Welded to Body Frame | More protection, Prevents Container from Shifting |

| Wear Strips | 1/2" x4" Wear Strips | Prevents Damage to Body's Deck |

| Access Panels | Front & Rear of Body | Easy Access to All Components |

| Body Frame Mounts | (4)1/2" Tie Down Rod with 1/2" Plate (8) 5/8"x 2 1/2" Plate with Grade 8 Nuts |

Longer Life than Bolt Clamps Welded to Body, Bolted to Truck Frame |

| ARM CONSTRUCTION | ||

| Arm Construction | 1/2" Steel, One Solid Plate, Square Construction | Square Design is Stronger and Provides Consistant Strength. |

| Arm Hinges | Pin/Collar with Grease Zerks | Long Life Expectancy, Easier Maintenance |

| Drop Pins | Replaces Load Shaft | Easy to repair/replace. Saves hours of labor |

| Cross Bar | 3" 1018 Cold Bar | Stronger and Higher Yield, Lasts longer |

| HYDRAULIC CYLINDERS | ||

| Arm Cylinder | 9 1/2" ID, 3 1/2" Chrome Shaft | All Welded Construction with drop pin connection |

| Contact Cylinder | 2 1/2" shaft w/ Snap Ring for Quick Repair | Can be fixed without removing cylinder from truck |

| Outriggers | Hydraulic Vertical | Fully Enclosed for Protection with Easy Access |

| LOADING & DUMPING OPERATION | ||

| Contact Cylinder | 2 1/2" shaft w/ Snap Ring for Quick Repair | Can be Fixed Without Removing Cylinder from Truck |

| Contact Cylinder Hose | Inside Lift Arm | Protects Hose from Premature Wear |

| Lift Hooks (Front) | 2-4 hole | Largest Versatilty of Containers Can Be Used |

| Dump Keys | Replaced "J" Hook | Safer and Significantly More Controlled Operation |

| Saddle Blocks | 3" x 8" Flame Cut | Allows Chain to Swivel for Level Operation |

| Chain | 5/8" High Alloy Chain | |

| U-Bolts | 1/2"x24" U-Bolt | |

| HYDRAULIC CYLINDERS | ||

| Hydraulic Flow Rate | 30 Gallons Per Minute | |

| Hydraulic LInes | Under Body with Access Panel | Easier to Replace and Simpler Routing |

| Hoses | 3000 PSI with Nylon Sleeves | Safety and Driver Protection is Paramount |

| Oil Tank | 50 Gallon, Truck Fame Mount | Out of Harms Way, Easy to Fill |

| Hydraulic Pump | P-51 Pump | 3000 PSI Operating Pressure |

| Valve | Commercial Valve | Rugged and Reliable Valve |

| In-Cab Controls | Air | Feathering Controls for Precise Operation |

| LIGHTING - ALL L.E.D | ||

| Side Marker, Rear Marker, Reverse, STT, 3- Bar Cluster, License Plate |

| SPECIFICATIONS | ACE | BENEFITS |

| Gross Lifting Capacity | 40,000 lbs. | |

| Container Capacity | 6-28 Cubic Yards | 4 Cu. Yards More Than Any Competitor's Lugger |

| Dump Degree | 120° | Controlled Dump and Less "Stringing" of Material |

| Arm Length | 120" | Versatility of Container Sizes |

| Operating Pressure | 2300 PSI | |

| Weight Distribution | Best in class | Arm Hinge is above bed. This allows the container to be brought 16" farther forward towards the cab. |

| Cycle Time | Lowered Position Raised Position |

56 Seconds 46 Seconds |

| BODY CONSTRUCTION | ||

| Subframe | 10" Structural Channel | Industry Standard |

| Side Boxes | 1/2" Plate | Thicker and Higher Yield Steel. Longest Life |

| Body Floor | 5/16" Formed | |

| Hinge Pins | 3" with Grease Zerks | Higher Yield & Heavier Duty |

| Walking Steps | Both Driver and Passenger Side | Easy Access From Any Direction |

| Cab Protector | 3/8" Angle Iron Welded to Body Frame | More protection, Prevents Container from Shifting |

| Wear Strips | 1/2" x4" Wear Strips | Prevents Damage to Body's Deck |

| Access Panels | Front & Rear of Body | Easy Access to All Components |

| Body Frame Mounts | (4)1/2" Tie Down Rod with 1/2" Plate (8) 5/8"x 2 1/2" Plate with Grade 8 Nuts |

Longer Life than Bolt Clamps Welded to Body, Bolted to Truck Frame |

| ARM CONSTRUCTION | ||

| Arm Construction | 1/2" Steel, One Solid Plate, Square Construction | Square Design is Stronger and Provides Consistant Strength. |

| Arm Hinges | Pin/Collar with Grease Zerks | Long Life Expectancy, Easier Maintenance |

| Drop Pins | Replaces Load Shaft | Easy to repair/replace. Saves hours of labor |

| Cross Bar | 3" 1018 Cold Bar | Stronger and Higher Yield, Lasts longer |

| HYDRAULIC CYLINDERS | ||

| Arm Cylinder | 9 1/2" ID, 3 1/2" Chrome Shaft | All Welded Construction with drop pin connection |

| Contact Cylinder | 2 1/2" shaft w/ Snap Ring for Quick Repair | Can be fixed without removing cylinder from truck |

| Outriggers | Hydraulic Vertical (Fixed) | Fully Enclosed for Protection with Easy Access |

| LOADING & DUMPING OPERATION | ||

| Contact Cylinder | 2 1/2" shaft w/ Snap Ring for Quick Repair | Can be Fixed Without Removing Cylinder from Truck |

| Contact Cylinder Hose | Inside Lift Arm | Protects Hose from Premature Wear |

| Lift Hooks (Front) | 2-4 hole | Largest Versatilty of Containers Can Be Used |

| Dump Keys | Replaced "J" Hook | Safer and Significantly More Controlled Operation |

| Saddle Blocks | 3" x 8" Flame Cut | Allows Chain to Swivel for Level Operation |

| Chain | 5/8" High Alloy Chain | |

| U-Bolts | 1/2"x24" U-Bolt | |

| HYDRAULIC CYLINDERS | ||

| Hydraulic Flow Rate | 22 Gallons Per Minute | |

| Hydraulic LInes | Under Body with Access Panel | Easier to Replace and Simpler Routing |

| Hoses | 3000 PSI with Nylon Sleeves | Safety and Driver Protection is Paramount |

| Oil Tank | 50 Gallon, Truck Fame Mount | Out of Harms Way, Easy to Fill |

| Hydraulic Pump | P-50 Pump | 3000 PSI Operating Pressure |

| Valve | Commercial Valve | Rugged and Reliable Valve |

| In-Cab Controls | Air | Feathering Controls for Precise Operation |

| LIGHTING - ALL L.E.D | ||

| Side Marker, Rear Marker, Reverse, STT, 3- Bar Cluster, License Plate |

| SPECIFICATIONS | ACE | BENEFITS |

| Gross Lifting Capacity | 35,000 lbs. | |

| Container Capacity | 6-24 Cubic Yards | 2 Cu. Yards More Than Any Competitor's Lugger |

| Dump Degree | 120° | Controlled Dump and Less "Stringing" of Material |

| Arm Length | 120" | Versatility of Container Sizes |

| Operating Pressure | 2300 PSI | |

| Weight Distribution | Best in class | Arm Hinge is above bed. This allows the container to be brought 16" farther forward towards the cab. |

| Cycle Time | Lowered Position Raised Position |

56 Seconds 46 Seconds |

| BODY CONSTRUCTION | ||

| Subframe | 10" Structural Channel | Industry Standard |

| Side Boxes | 5/16" Plate | Equivalent to our Competition's 40,000 lbs. Hoist |

| Body Floor | 1/4" Formed | |

| Hinge Pins | 3" with Grease Zerks | Higher Yield & Heavier Duty |

| Walking Steps | Both Driver and Passenger Side | Easy Access From Any Direction |

| Cab Protector | 3/8" Angle Iron Welded to Body Frame | More protection, Prevents Container from Shifting |

| Wear Strips | 1/2" x4" Wear Strips | Prevents Damage to Body's Deck |

| Access Panels | Front & Rear of Body | Easy Access to All Components |

| Body Frame Mounts | (4)1/2" Tie Down Rod with 1/2" Plate (8) 5/8"x 2 1/2" Plate with Grade 8 Nuts |

Longer Life than Bolt Clamps Welded to Body, Bolted to Truck Frame |

| ARM CONSTRUCTION | ||

| Arm Construction | 1/2" Steel, One Solid Plate, Square Construction | Square Design is Stronger and Provides Consistant Strength. |

| Arm Hinges | Pin/Collar with Grease Zerks | Long Life Expectancy, Easier Maintenance |

| Drop Pins | Replaces Load Shaft | Easy to repair/replace. Saves hours of labor |

| Cross Bar | 3" 1018 Cold Bar | Stronger and Higher Yield, Lasts longer |

| HYDRAULIC CYLINDERS | ||

| Arm Cylinder | 9 1/2" ID, 3 1/2" Chrome Shaft | All Welded Construction with drop pin connection |

| Contact Cylinder | 2 1/2" shaft w/ Snap Ring for Quick Repair | Can be fixed without removing cylinder from truck |

| Outriggers | Hydraulic Vertical (Fixed) | Fully Enclosed for Protection with Easy Access |

| LOADING & DUMPING OPERATION | ||

| Contact Cylinder | 2 1/2" shaft w/ Snap Ring for Quick Repair | Can be Fixed Without Removing Cylinder from Truck |

| Contact Cylinder Hose | Inside Lift Arm | Protects Hose from Premature Wear |

| Lift Hooks (Front) | 2-4 hole | Largest Versatility of Containers Can Be Used |

| Dump Keys | Replaced "J" Hook | Safer and Significantly More Controlled Operation |

| Saddle Blocks | 3" x 8" Flame Cut | Allows Chain to Swivel for Level Operation |

| Chain | 1/2" High Alloy Chain | |

| U-Bolts | 1/2"x24" U-Bolt | |

| HYDRAULIC CYLINDERS | ||

| Hydraulic Flow Rate | 22 Gallons Per Minute | |

| Hydraulic LInes | Under Body with Access Panel | Easier to Replace and Simpler Routing |

| Hoses | 3000 PSI with Nylon Sleeves | Safety and Driver Protection is Paramount |

| Oil Tank | 50 Gallon, Truck Fame Mount | Out of Harms Way, Easy to Fill |

| Hydraulic Pump | P-50 Pump | 3000 PSI Operating Pressure |

| Valve | Commercial Valve | Rugged and Reliable Valve |

| In-Cab Controls | Air | Feathering Controls for Precise Operation |

| LIGHTING - ALL L.E.D | ||

| Side Marker, Rear Marker, Reverse, STT, 3- Bar Cluster, License Plate |

| FEATURES | STANDARD DETAILS |

| Container Sizes | With an Ace Super Series Lugger Hoist, you can utilize larger containers than ever before! Ace Super Series Luggers can lift and dump any container between 6-30 cubic yards. That is 6 cubic yards more than any our Competitor’s lugger hoists! Ace offers over 300 different configurations of Lugger Containers suited for every application. |

| Dumping | Ace Super Series Luggers use our patented “Dump Key” in lieu of a “J-Hook” Style Dump Plate. This ensures a higher degree of control and larger containers are now possible. Our “Dump Keys” allow the operator to dump the load perfectly every time, which cannot be said for our competition’s lugger hoists. Most importantly, Ace's Dump Keys offer the safest dump style of any lugger on the market. |

| Longevity | Ace positions the necessary material in the correct location to ensure years of excellence. The average Ace Lugger Hoist last 25 years. Some of our customers have had the same Ace Lugger Hoist for over 40 years. |

| Maintenance | Every aspect of the unit is mechanic friendly. If you’re one of the many customers who have both Ace Lugger Hoists and Ace Roll-Off Trailers, many of the cylinder components are interchangeable from an Ace Lugger to an Ace Roll-Off Trailer. |

| Performance | There is not a lugger hoist on the market that will out lift and outperform an Ace Super Series Lugger Hoist. Each unit is tested and rated to respective lifting capacity. Our 50,000 lbs. Hoist will lift 50,000 lbs. while the truck is idling. The same is true for any other lugger hoist we produce. We have been told but numerous Ace Lugger users that “Nothing will out Lift an Ace”. Each unit is produced with the most abusive environment in mind. |

| Weight Distribution | On average Ace Lugger Users achieve a 33% better weight distribution than units produced by other lugger hoists manufacturers. This is possible because an Ace Lugger Hoist allows the container to be placed 36” farther forward on the deck. This allowed the container to be centered evenly between the steer axle and the rear tandem. As a result, our users have experienced less overweight fines than our competition’s customers. Ask almost any user of our competition’s units, their biggest issue is weight distribution. |

| Tarping System |

| Aluminum Wheels |

| Air Ride Suspension |

| Lift/Drop Axle(s) |

| Auto-Grease System |

| Auto-Tire Inflate |

| In-Cab Controls |

| Removable Stops |

| Tool Box |

| Wireless Remote Control |

| Scale System |

| Inside/Outside Rail |

| Dead Lift |

| Hydraulic Cable Winch |

| And Many More! |